There is a serious selling challenge like salespeople have never faced before. Sales on the Internet are continually on the rise. However, other forms of selling are becoming more and more challenging. As a result of the Internet, buyers are more knowledgeable today. Research shows that 70% of a purchasing decision is made before a salesperson is engaged.

There is a serious selling challenge like salespeople have never faced before. Sales on the Internet are continually on the rise. However, other forms of selling are becoming more and more challenging. As a result of the Internet, buyers are more knowledgeable today. Research shows that 70% of a purchasing decision is made before a salesperson is engaged.

Companies see their sales declining and think training or a CRM package will fix the problem. Unfortunately, unlike other areas, decisions about a sales or marketing fix are made before the real problem is defined and analyzed. Management in these areas focuses on results rather than on the process that produces the results. Managers typically apply “solutions” based on gut feel, the latest new CRM, or sales training package. In most cases, it is not the salespeople; it is the sales process that is the problem.

As a salesperson, sales manager and as a trainer/developer, I have seen management spend thousands or even hundreds of thousands to fix a sales or marketing issue only to see a lack of results. Many executives begin with demanding more leads or holding a sales contest. When that doesn’t get the results they want, they buy the latest and greatest sales training program or a CRM package. Others try a variety of reconfigurations such as reassigning sales territories or arranging the sales force by industry, while others arrange the assigned accounts by size. None of these solve the problem because the company has not identified the real problem. The sales training may not have addressed the skills that are deficient. Also, a one size fits all approach may anger or frustrate you top performers and yet be too challenging or not have enough practice for the low performers. The CRM solution is only as good as the data entered and sales contests don’t work if motivation isn’t the problem.

Let’s take a look at why these fixes did not work, and then I trust you will have an ah-ha moment when I explain where the real problem lies and how to go about fixing it.

Before you can apply a solution that fixes the problem, you have to locate the real problem. It may be in sales, or it may be elsewhere in the company. All departments are interrelated. Take a look at the big picture. An idea becomes a product design. It is manufactured and then promoted by marketing. Leads are generated, and salespeople are engaged to perform their activities. The prospect moves forward in the buying cycle, is put on the back burner for the future, or is eliminated as a prospect. The customer continues in the buying process and then makes a purchase. Finally, the product is delivered, installed if required, and the customer is billed. The company continues contact related to customer support, tech support, or update notices.

The problem could lie anywhere in the end-to-end process. It could be the product is too expensive because it has so many unnecessary bells and whistles, or the product could be too complicated to operate. It could be in the organization or the pricing structure. Maybe marketing is using the wrong marketing tactics to attract leads. Perhaps the problem is the sales people are failing to follow-up, or they are engaging prospects in the wrong conversation. Only with data and facts can you analyze the cause and effect of each activity. With this information, you can see if an activity contributes to sales success, causes problems, or causes the customer not to make a purchase.

Everyone wants a silver bullet to fix the problem, but there is no silver bullet to solve the problem. Quality processes like Lean and Continuous Improvement provide the best methods for identifying, analyzing and solving problems. Many managers, as well as salespeople, think that these processes are based on complex math calculations and apply only to manufacturing. They don’t have the information to identify the problem, or they reject the idea of applying the Lean processes to sales or marketing. However, companies are beginning to apply the processes to both sales and marketing and are achieving great success. These companies are eliminating waste, improving revenue and helping sales close more business. In manufacturing productivity can be increased as much as 82%, quality can be improved 49%, and absenteeism reduced 58%, and sales can achieve similar results.

Lean has been applied to healthcare, accounting, government, education, and software development, why not to sales? Yes, each of these disciplines is unique, but just as Lean has been applied to them, it can be applied to sales. Companies that have implemented Lean Six Sigma in manufacturing have meticulously applied the tools including those with complex math calculations. However, there are tools and processes that do not include complex math calculations, and they are less challenging to get buy-in from salespeople and their managers.

Since resistance is especially strong in the early stages and from both sales and management, the less scrupulous version is a good entry into the process. You will achieve success that you can build upon and then perhaps move to the more rigorous version for the highest level of success.

Where do you start? Well, it is essential to understand some basic principles before you begin to do anything. Let’s start with Lean. It is a process to eliminate waste and improve efficiency and effectiveness. You can employ Lean principles and use the easier tools of the Six Sigma business improvement process to begin. The basic principles of Lean as applied to sales are:

- Create value as defined by the end customer.

- Identify and map all the steps in the value stream or end-to-end sales process and wherever possible eliminate steps that don’t add value.

- Complete all of the steps in the value stream or sales process as quickly as possible so it will flow smoothly and allow the buyer to make an informed decision that they will not regret.

- Identify problems in areas in other areas that impact sales, communicate the impact and request management fix the problem.

- Empower the salespeople or sales manager to apply continuous improvement to the value stream map and the sales process. It will allow them to remain current and continue to add value.

The number one reason for the failure of success with applying Lean to any area of a company is the lack of senior management engagement. Continuous improvement and Lean must become a way of life at the company, and the senior managers must support and use the processes. It cannot be just a slogan on the wall or an article in the company communication. When I worked at Xerox, everyone from David Kerns, CEO on down was required and empowered to use the quality processes. It became so ingrained in me that I insisted on using it in my volunteer activities as well as my personal life.

Also, if you hire a black belt or other Continuous Improvement professional to assist you, they must be able to express the findings and solutions in terms related to the company, sales and marketing strategies and goals. Many such experts communicate in “statistical speak”, and that is a turn off to executives, sales, and marketing.

To get the salespeople to buy-into a new process such as Lean or Continuous Improvement, you must make the process easy and show them how it can help them make more sales easier and faster. Remember that salespeople do not like to input data, especially when they believe it will be used against them. Management must state and demonstrate that the goal of a change in process is to help them sell and to add revenue to the company as well as have delighted customers.

In the first stage of your project, you will need to define the problem and get to the root cause. A Six Sigma tool that can help you succeed in applying Lean is the DMAIC. This acronym stands for Define, Measure, Analyze, Implement and Control.

In this blog post, I will cover the define stage. That will be enough to digest along with the big picture I provided. I’ll cover the other phases of the tool in future posts.

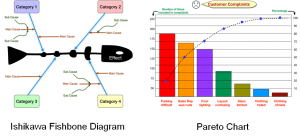

I suggest you begin by getting two points of view. First get the sales perspective. They are closest to the problem. Hold brainstorming sessions in each area or with a representative from each sales area. You can use two simple tools. The Fishbone diagram which is a cause and effect diagram that gets its name from the skeleton of a fish that it resembles. You can also use a Pareto chart to identify which problem occurs most often. I have included examples of each below.

The tools displayed do not include complex mathematical calculations, but they do provide insight into the problem and can help management make changes. Without data on the problem causes and effects, management cannot determine what changes will be effective.

The second point of view I suggest is the Voice of the Customer. You can create a survey for the internet, direct mail or phone calls to a focus group of customers that bought and those that did not buy. The data can provide significant insight. This research must be done carefully. Everyone creating and asking the questions must be trained in the proper creation of questions and how they should be asked. You don’t want to influence the response either positively or negatively. Customers and those that didn’t buy want to feel free to express their real opinion.

It is important to identify not only the customer issues preventing sales but also the wants and needs of the customer. If the deal is complex, many people in both your company and the customer company may be involved. Therefore, you need to understand how the customer views the whole company. Once you have the data, you can map the value stream or sales process and the strategies, issues, challenges as well as what buyers want and the value to them.

The results will help you define qualified leads and develop a sales process that meets their needs. Describing what defines a qualified lead is a process that is not effectively used by most companies. Yet, it can avoid wasted costs and efforts. This part of the process alone can be very beneficial. The seller cannot afford to waste time with a prospect that does not seriously intend to make a purchase.

How do you know what is a good sales opportunity? It is important to ask qualifying questions early in the sales cycle. Then you can either put the prospect on the back burner as the timing is not right or eliminate them as they are not a good fit for your product or service.

Your sales will soar when you don’t waste time with suspects that will never make a purchase, and you spend time with prospects that will make a purchase. You’ll also have a higher return on investment as fewer prospects will fall out of the process later in the cycle when you have invested time.

This post contained a lot of information to digest yet it provides a basis for you to consider implementing Lean or Continuous Improvement in your organization. Since this topic is so broad, I have decided to break it into smaller bites. That approach will make it easier to understand and give you time to think about it in your organization. Therefore, I will continue with the next section on Measurement and Analysis in the sales process in the next blog post.

Resources for getting started with LEAN:

Liker, Jeffery K, (2004). The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer. New York: McGraw-Hill.

Mann, David, (2010). Creating A Lean Culture: Tools to Sustain Lean Conversions (3rd Edition), Boca Raton: CRC Press.

Rother, Mike, (2010). Toyota KATA: Managing People for Improvement, Adaptiveness, and Superior Results. New York: McGraw-Hill

George, M., Rowlands, D., Price, M., Maxey, J. (2005) The Lean Six Sigma pocket toolbook: a quick reference guide to nearly 100 tools for improving process quality, speed and complexity. New York, N,Y: McGraw-Hill

About the Author: Phyllis Mikolaitis is a sales coach, author, and speaker with over 30 years’ global experience. She is dedicated to taking you beyond the typical “how to” courses to the heart of persuasion techniques incorporating insights and stories to win the sale. Phyllis has also had training in Leadership Through Quality, Six Sigma and Lean. She is certified in Process Improvement in Print and is now working with organizations on Lean and People-Centered Leadership. Visit Phyllis and her business partner John Switzer on other pages on this site www.salestrainingsolutions.com. The links on our website allow you to listen to our podcasts or catch up on past blog posts on this and other sales topics. For Lunch and Learn sessions, face-to-face or virtual training and coaching contact us at 703-819-5872.